Copyright © Huizhou Sandao New Material Co., Ltd. All Rights Reserved. Site Map

- +86-13825203943

- sandao08@hksandao.cn

- No. 51, Yanjiang Road, Liaozai Village, Yuanzhou Town, Boluo County, Huizhou City, Guangdong Province

Features: This product is a one-component, dealcoholized organosilicon compound in a white paste form. It exhibits excellent resistance to acids, alkalis, aging, corrosion, radiation, and weathering, and can be used in temperatures ranging from -60°C to 250°C. It also exhibits excellent electrical insulation, flame retardancy, and bonding properties, fully meeting the bonding requirements of electronic components.

Environmental protection requirements: Comply with RoHS directive and related environmental protection requirements

Reference standard: HG/T 3947-2007 One-component room temperature vulcanizing silicone adhesive/sealant

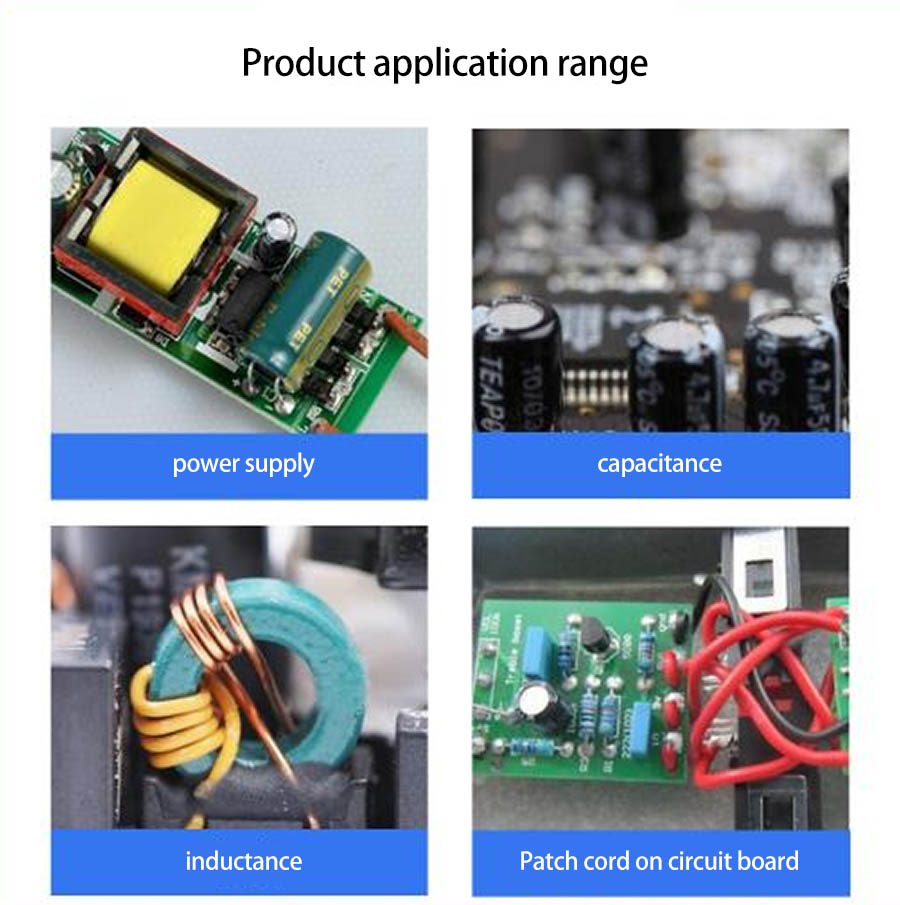

Application

Used for bonding and filling between electronic and electrical products. Bonding and filling between circuit boards and other materials, with excellent adhesion and no corrosion to copper and PC (polycarbonate).

Electrical/mechanical properties (At TA=25℃)

Parameter | Symbol | Test standards | Performance indicators |

Hardness shore A | HA | GB/T 531.1 | 65 ± 5 |

Elongation% | δ | GB/T 528 | ≥ 150 |

Tensile strength MPa | R m | GB/T 528 | ≥ 2.0 |

Shear strength MPa | σc | GB / T 7124 | ≥ 2.0 |

Dielectric strength kV /mm | eo | GB/T 1695 | ≥ 2 0 |

Dielectric constant 1.0 MHz | ε | GB/T 1693 | 2.8 |

Volume resistivity Ω · cm | ρ | GB/T 1692 | ≥1.0×1013 |

Linear shrinkage% | r | HG/T 2625 | ≤0.6 |

Breakdown strength kV/mm | / | GB / T 1695 | ≥ 2 0 |

AC withstand voltage kV | / | ASTM D149 | ≥6 |

Absolute Maximum Ratings (At TA=25 °C )

Parameter | Symbol | Numerical | unit |

Tack-free time | TFT | ≤ 10 | min |

Curing time | TFT | ≤ 24 | H |

proportion | sg | 1.6±0.1 | g/cm³ |

flame retardant | V | V-0 | UL-94 |

Operating temperature | T OPR | -60 °C To + 250 ° C | |

Storage temperature | T STG | 0 °C To + 25 °C | |

Usage instructions and precautions

Clean the bonding and sealing surface , cut off the seal at the top of the pointed nozzle according to the amount to be used, install it on the packaging mouth, apply it to the construction surface (the thickness should not exceed 6mm) , and place it in the air. The surface of this product will lose its stickiness (touch dry) at room temperature for 3-10 minutes and will be completely cured after 24 hours . Heating this product will not significantly change its curing speed.

Unused rubber should be stored sealed . If a small crust forms on the seal before reuse, simply remove it, this will not affect normal use. During storage, the rubber may solidify slightly at the tube opening. This can be removed and normal use will resume without affecting product performance. The shelf life is 6 months (at 25 ° C).

This product is not dangerous, but keep out of mouth and eyes.

This product cannot be mixed with other types of colloids!

Packaging, storage and transportation requirements

Transport: No regulations for domestic (CN-GB) or international (IMO, IATA, UN). Non-dangerous goods.

Package:

1.The packaging of materials has a certain protective and sealing effect on the materials, ensuring that the materials are not damaged during transportation.

2.The packaging box should have information such as product model, name, quantity, manufacturer’s trademark, production batch, etc.

3.The packaging box should meet the requirements of moisture-proof, shock-proof, pressure-proof and mildew-proof.

store:

Products packaged in boxes should be stored in a cool and dry environment with an ambient temperature below 26 °C. There should be no acidic, alkaline or other corrosive gases in the surrounding air. Under the above conditions, the product can be stored for six months from the date of production and the material will still be qualified during these six months.

Packaging specifications: 100ml aluminum tube , 300ml PE tube , 2600ml PE tube