Copyright © Huizhou Sandao New Material Co., Ltd. All Rights Reserved. Site Map

- +86-13825203943

- sandao08@hksandao.cn

- No. 51, Yanjiang Road, Liaozai Village, Yuanzhou Town, Boluo County, Huizhou City, Guangdong Province

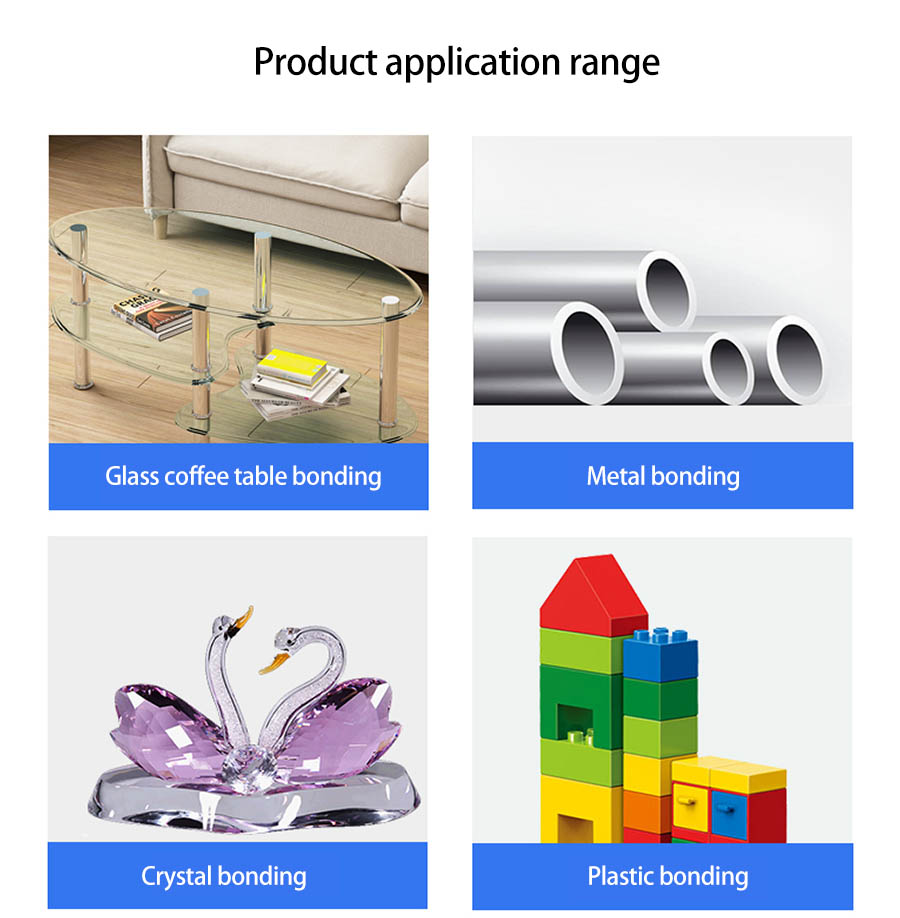

In modern industrial manufacturing, PVC (polyvinyl chloride) materials are widely used in construction, electronics, automotive, and other fields due to their excellent physical properties, chemical stability, and processability. However, the bonding and sealing of PVC materials have long been challenging for manufacturers. This article presents a success case of Sandao SD622M UV curing adhesive in PVC material applications, demonstrating its outstanding bonding performance and curing efficiency.

1. Project Background

A PVC product manufacturer encountered issues such as weak bonding and long curing times during production. These problems not only affected product quality and production efficiency but also increased manufacturing costs. To address these challenges, the manufacturer sought a high-performance adhesive to improve both the bonding effectiveness and curing speed of PVC materials.

2. Product Selection

After market research and technical comparisons, the manufacturer selected Sandao SD622M UV curing adhesive. Sandao SD622M is a UV-curable adhesive that undergoes rapid chemical reactions upon exposure to ultraviolet light, offering advantages such as fast curing, high post-curing strength, excellent transparency, and environmental friendliness. These characteristics make it an ideal choice for bonding PVC materials.

3. Application Process

Surface Treatment: Before bonding, the PVC material surfaces were thoroughly cleaned to remove oil, dust, and other impurities, ensuring a clean and tidy bonding area. Additionally, the surfaces were appropriately sanded to enhance bonding effectiveness.

Adhesive Application: Using specialized dispensing equipment, Sandao SD622M UV curing adhesive was evenly applied to the bonding areas of the PVC materials. Thanks to its excellent flow properties and ease of application, the adhesive ensured uniform distribution across the surfaces.

UV Curing: The PVC materials coated with the adhesive were placed under UV curing equipment for irradiation. Under UV light, the photoinitiators in Sandao SD622M absorbed energy and decomposed into free radicals or cations, triggering polymerization reactions with monomers or oligomers in the adhesive. This process formed a cross-linked network structure, rapidly transforming the adhesive from liquid to solid. The curing process was typically completed within seconds to minutes, significantly improving production efficiency.

4. Application Results

Through practical application, Sandao SD622M UV curing adhesive delivered remarkable results in PVC material bonding. Firstly, its fast curing speed greatly shortened production cycles and enhanced efficiency. Secondly, the high bonding strength after curing met the requirements of PVC products even in harsh environments. Additionally, the adhesive's high transparency and environmental friendlessness improved both the appearance and sustainability of PVC products.

5. Conclusion

The success case of Sandao SD622M UV curing adhesive in PVC material applications demonstrates its excellent performance and broad prospects. By adopting appropriate application methods and processes, the bonding effectiveness and curing speed of PVC materials can be significantly improved, providing strong support for the manufacturing and application of PVC products.

In the future, with continuous advancements in UV curing technology and expanding market demands, Sandao SD622M UV curing adhesive will play an increasingly vital role in the PVC material sector, offering higher quality and more efficient services for the manufacturing and application of PVC products.