Copyright © Huizhou Sandao New Material Co., Ltd. All Rights Reserved. Site Map

- +86-13825203943

- sandao08@hksandao.cn

- No. 51, Yanjiang Road, Liaozai Village, Yuanzhou Town, Boluo County, Huizhou City, Guangdong Province

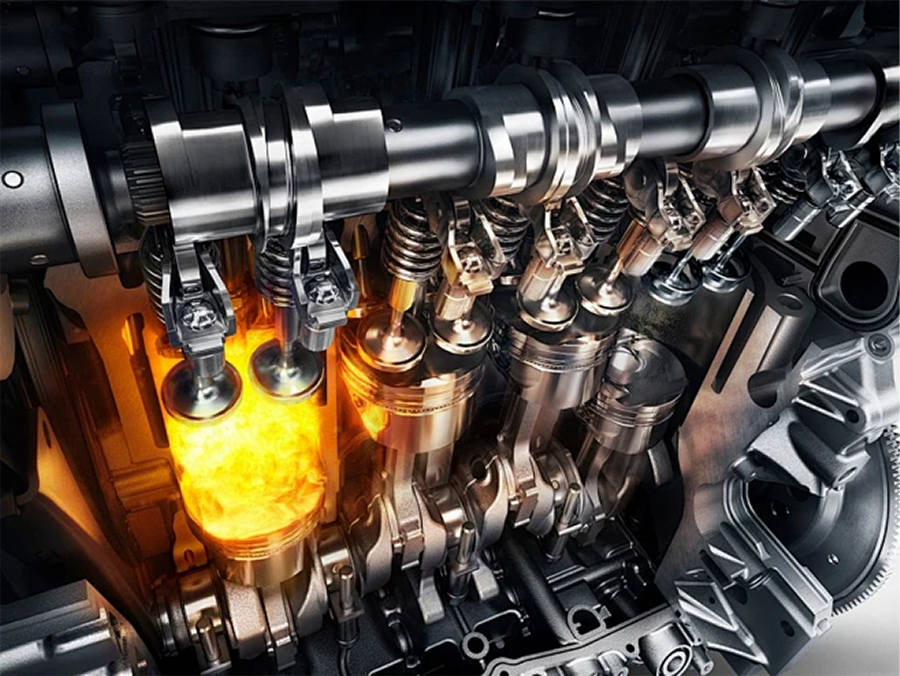

The bonding parts of the automotive power system mainly include the fastening and sealing of screws and bolts, and the sealing of cylinder gaskets. Anaerobic adhesives are more commonly used in the automotive manufacturing industry. They are used for thread fastening and locking, fixing of mating parts, flat bonding, sealing of pipes and flanges, and pinhole sealing. They can solve problems such as anti-loosening and anti-leakage, and simplify the assembly process.

Various types of anaerobic adhesives are primarily used to seal sand holes created during engine casting, various bolt fastenings, pipeline seals, and surface seals in automotive power systems. Water glass impregnation has poor sealing effectiveness, while high-temperature resistant anaerobic adhesive impregnation can achieve excellent sealing results.

High-strength anaerobic adhesives can be used for retaining and sealing engine cylinder heads and transmission studs, as well as bolts that are rarely disassembled, components, cylindrical bowl-shaped plugs, drive axle differential case connecting bolts, and bolts securing round shaft gears to differentials. Furthermore, automotive gaskets cannot guarantee sealing performance and the geometric accuracy of connected components. Using anaerobic adhesives for flat sealing can address these issues. Low- strength anaerobic adhesives can be used for easily disassembled parts.

Adhesives used in automotive powertrains typically need to possess high-temperature, high-pressure, oil-, and water-resistant properties to ensure they maintain adhesion even in complex operating environments. Generally speaking, adhesives used in automotive powertrains primarily include high-temperature adhesives, sealants, structural adhesives, and specialty adhesives.

Specifically, for example, in engine components, high-temperature resistant adhesives are needed to fix and seal high-temperature components such as crankcases and cylinder heads. In the transmission system, wear-resistant and oil-resistant adhesives may be used to fix transmission components. In the exhaust system, high-temperature resistant and corrosion-resistant sealants are needed to seal the exhaust pipe interfaces.

Regarding the specific adhesive selection and use, we recommend consulting a professional automotive maintenance technician or manufacturer to ensure you select the adhesive suitable for your specific component and operating environment. Also, be sure to follow the instructions in the user manual to ensure safety and reliability.